Case study

Extending asset life and reducing waste through parts repair

Improving the turnaround time of parts repair, the Parts Recycling Centre delivers significant carbon reductions and financial savings for our partners.

The Parts Recycling Centre (PRC) launched in 2003 to improve the turnaround time of part repairs. Aligned with our partner's capital planning strategy, we support obsolete assets and extend asset life by up to 10 years. The solution is simple and effective, delivering significant carbon reduction and financial savings.

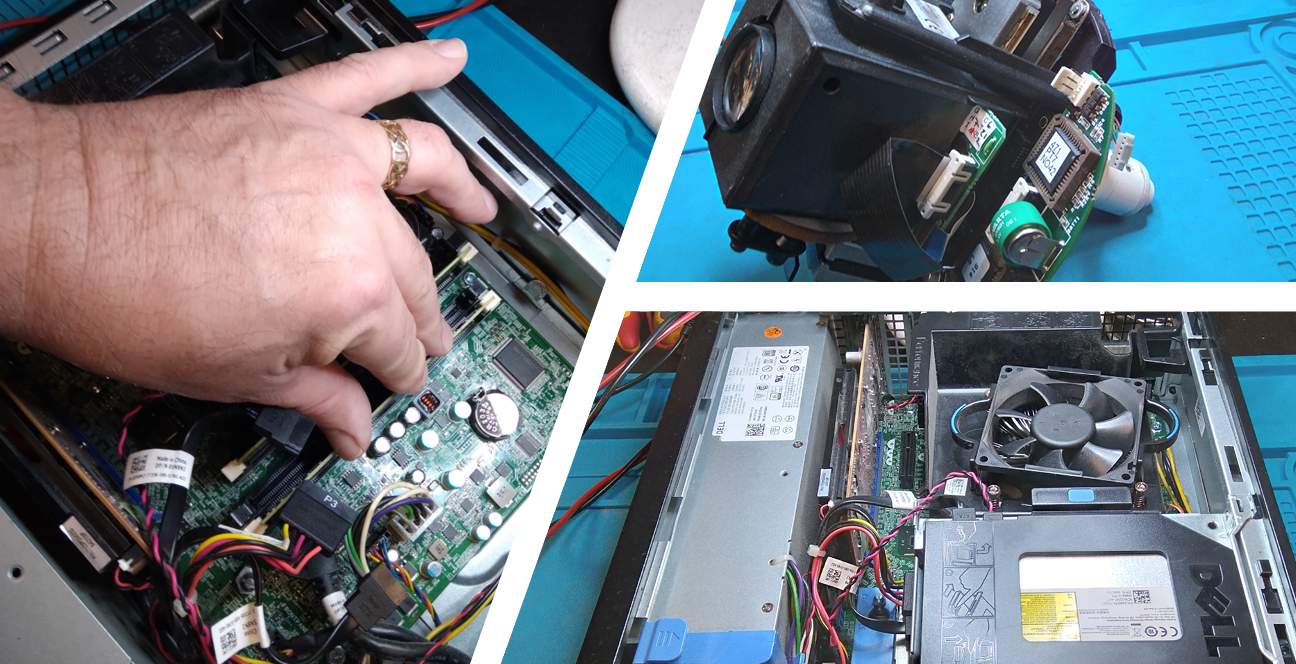

The benefits of in-house repair

When viable, we favour repair over new parts to reduce waste and cost. The specialist nature of some parts means that only a limited number of suppliers support their repair, and the turnaround can be up to 12 weeks. By delivering repair services in-house we offer our partners several benefits:

These benefits feed through to our partner’s customers by delivering a safer and comfortable environment, whilst supporting our partner’s value and sustainability goals.

Developing the PRC team

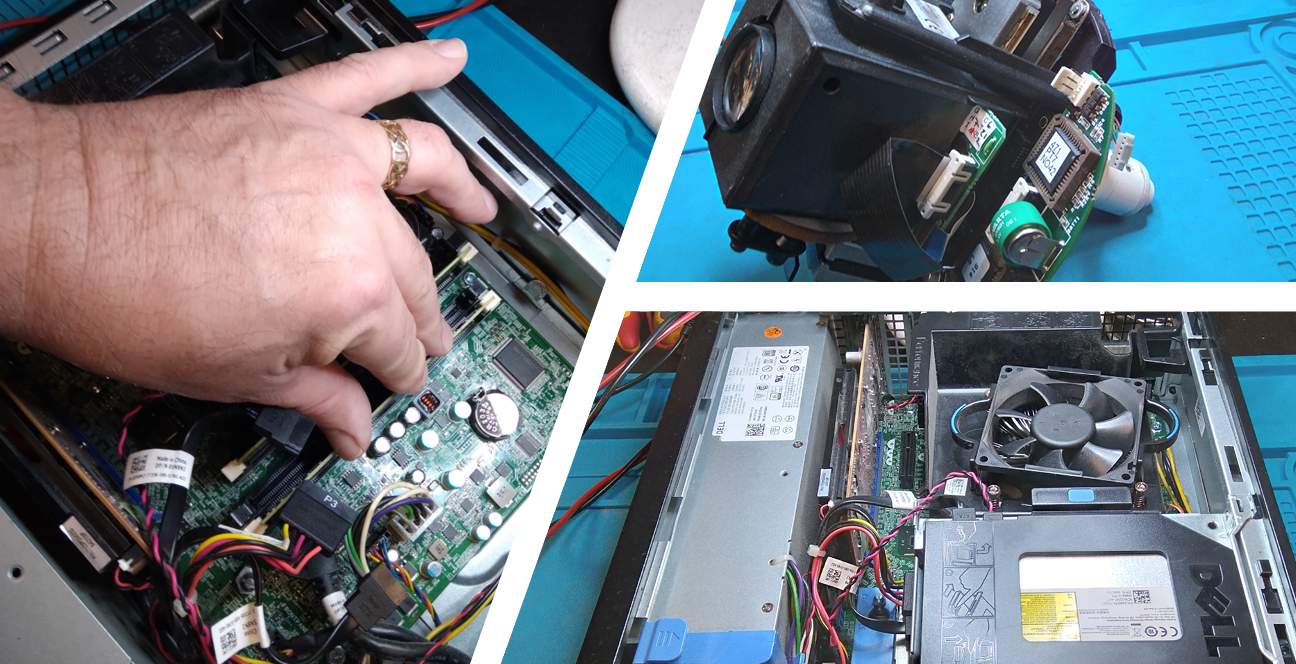

Since inception, the PRC has enhanced its repairs management to support the development of our partner’s assets and technology. In this time, many parts and assets have become obsolete or have been removed when new assets have been introduced. For example, the increase of surface-mounted technology on printed circuit boards requires considerable skill to rework.

Initially, only 30% of parts were repaired in-house. Through the following improvements, this figure is now 90%+:

The PRC is run by contract-dedicated teams who manage inventory, logistics, repairs and quality control.

Last year, the PRC repaired 35 tonnes of parts which would have otherwise been wasted, helping to mitigate issues of obsolete parts and increasing asset lifespan by up to 10 years.

Quantifying the value of the Parts Recycling Centre

In the last year, the PRC repaired 35 tons of parts, which would otherwise have been wasted. These parts support assets (80% of which are now obsolete) and elongates asset life by up to 10 years.

Benefits of the PRC:

Expanding the service to deliver greater value

We asses all new parts to decide if it’s cost effective for them to be repaired in-house or by third parties. In 2022, we're reviewing new asset categories for inclusion in the programme, which will enable the PRC to support an extra 550 assets, extending their life and supporting our collaborative sustainability strategy.

Whether you're considering changing facilities management provider or outsourcing maintenance services for the first time, our expert team is here to help.